» China wholesale Brewhouse - 500l Customized Micro Craft Beer Brewery For Sale With Two-Vessel Brewhouse System – CGBREW

» China wholesale Brewhouse - 500l Customized Micro Craft Beer Brewery For Sale With Two-Vessel Brewhouse System – CGBREW Detail:

Advantages of our euqipment

Customize and design the beer brewery equipment;

Competitive price and prompt delivery;

Main parts of the equipment 5 years warranty at free;

Provides all of Customs clearance document, Certificate of origin,CE,ISO certification system;

Professional engineers going aboard for the installation,debugging,repairing.

Company Introduction

Jinan China-Germany Brewing Co.,Ltd is a professional Micro brewery equipment produce company.

* Our company accumulated more than 25 Years of beer mash equipment manufacturing experience,and on the basis of lessons from the advanced technology of foreign beer equipment,combined with our own unique processing technology, formed our unique beer mash process and the high quality equipment.

Products Description

|

500L MICRO BREWERY EQUIPMENT SCONFIGURATION LIST (one option as reference) |

||

|

System |

Main machine |

Specifications

|

|

Milling System |

Malt mill machine |

300kg/h, stainless steel |

|

Heating System (optional) |

Electric heating |

with electric elements |

|

Brewhouse System (optional) |

Mash/Lauter Tun |

500L, Stainless Steel 304 |

|

Kettle/Whirlpool Tun |

500L, Stainless Steel 304, | |

|

Hot water tank |

1000L, Stainless steel 304 | |

|

Fermentation System(optional) |

Fermentation Tank |

6*1000L Top manway, Dimple cooling jacket |

|

Yeast Adding Tank |

Stainless Steel 304 | |

|

Cooling System |

Refrigerator machine |

2*4HP, Coopland inside |

|

Icw water Pump |

3T/H | |

|

Ice water tank |

1000L, with copper cooling coils | |

|

CIP Cleaning System |

Acid Tank |

2*100L, SUS304 full welded with a match control box |

|

Alkali Tank |

||

|

Cleaning Pump |

3T/H | |

|

Control System |

Control System |

Semi-automatic, temperature display |

Equipment details

A. Malt milling machine:

Capacity: >200kg/h;

Type: Roll-type briquetting press;

B. Brewhouse System:

Mash/Lauter Tun and Kettle/Whirlpool Tun

C. Fermentering system:

The volume of fermenters is as same as mash tun or twice of it. For different volumes,we can manufacture conical fermenter with large cone angle and small angle.We usually configure 6 pieces of fermenters.

For the manhole, we also have top opening and side opening for option.

D. Chilling system:

We configure one ice water tank and one cold water tank.

E. Refrigeration machine

Specification:4HP,Copeland inside.

F. Control system:

The control system includes electricity control cabinet and temperature meters.We have Siemens PLC control and Digital Panel control.

G. CIP cleaning system

(1) Sterilization tank :

steam heating jacket on tank wall; double wall; stainless steel 304

(2)Alkali liquor tank:

single wall;stainless steel 304

(3)Control box:

control the temperature of alkali tank;control CIP pumps

Auxiliary equipment

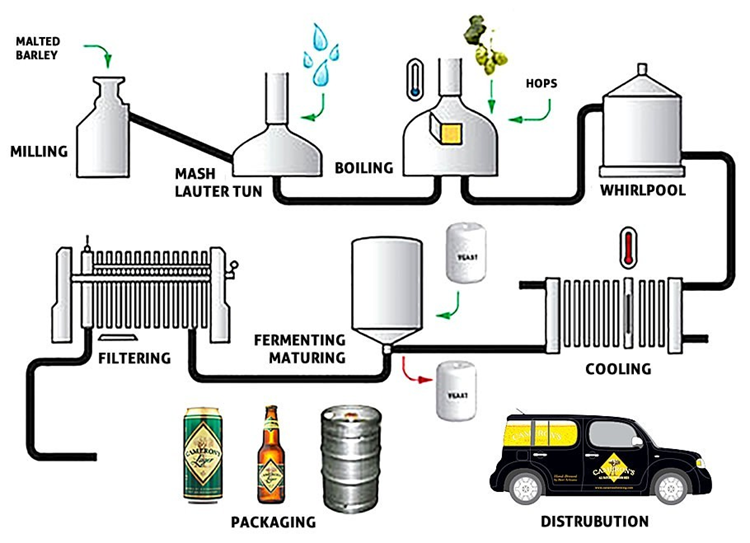

Flow chart of brewing process

Customer Feedback Photos

Product detail pictures:

Related Product Guide:

That has a sound small business credit, great after-sales service and modern production facilities, we've earned an outstanding standing amid our buyers across the earth for » China wholesale Brewhouse - 500l Customized Micro Craft Beer Brewery For Sale With Two-Vessel Brewhouse System – CGBREW , The product will supply to all over the world, such as: Holland, Philadelphia, Kuwait, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.